![]()

Hainan Sinyoung Rubber Machinery Limited Company

Tel: 0086-0898-65622879 (Ms. Wil)

WhatsApp:

+8613637580623 (Ms. Wil)

+8613707519087 (Ms. Flora)

Email:

Address: No.6, 5th cross road, Yunlong Industrial Park, Yunlong Town, Qiong Shan District, Haikou city, Hainan, China.

Products

Products

- Products Description

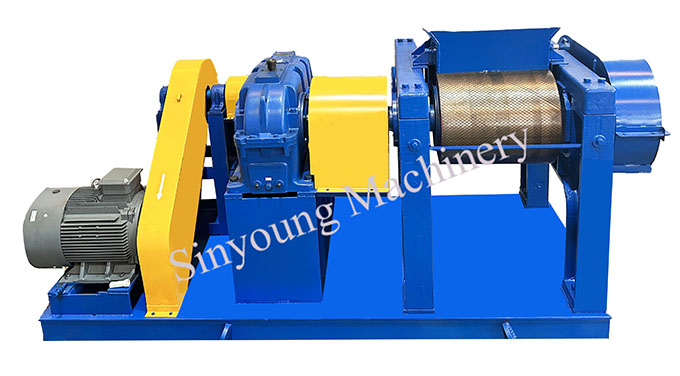

Product name: Creper

|

|

2 ton/hour |

3 ton/hour |

4 ton/hour |

5 ton/hour |

10 ton/hour |

|

Model |

SY-CP-350 |

SY-CP-450 |

SY-CP-450 |

SY-CP-560 SY-CP-610 |

SY-CP-660 |

|

Power |

22-30kw |

30-45kw |

30-45kw |

55-75kw |

90-110kw |

The creper is a kind of equipment for the production of creper, which can pass the extruded rubber raw material through the pressure and friction of the roller to form crepe sheets of different thickness. Our creper have the following features:

-The rollers of each machine have different speed ratios, speeds, and patterns, so that the thickness of the crepe can meet the production requirements and create conditions for improving the output of the production line.

- Our creper adopts high-quality materials and components, which guarantees the durability and stability of the equipment. The rollers are ductile iron, which is both wear-resistant and easy to feed. Large parts such as reducers, motors, bearings, couplings, and small parts such as V-belts, bolts, and sealing rings are selected from high-quality suppliers, which improves the life of components and prolongs the effective production time.

- Our crepe machines are designed with quick parts changes to reduce downtime. Key components such as bearings, couplings, gears, pulleys and other key components can be quickly replaced by disassembling nuts for easy maintenance.